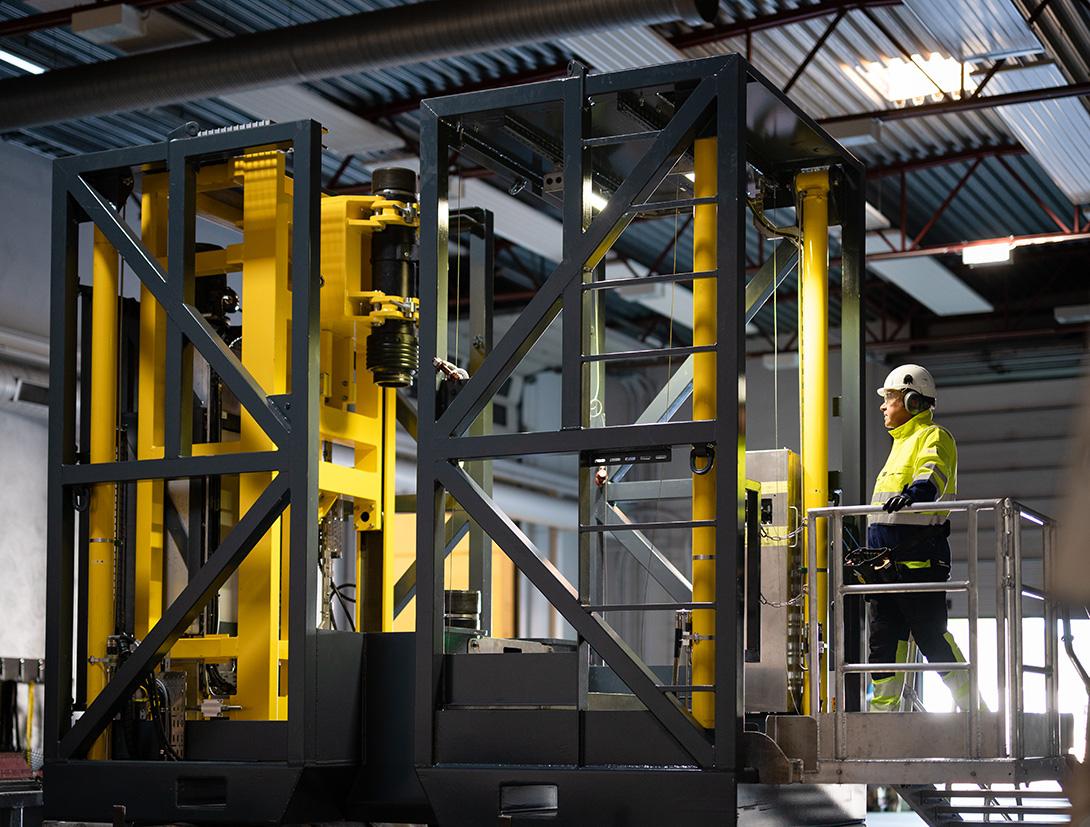

Making wireline procedures safer, faster, and more efficient

The rugged SafeFrame is the world’s first mechanical add-on solution that eliminates the need for manual handling of the lubricator.

With SafeFrame, oil and gas companies can now close the deviation in the “Aktivitetsforskriften” §92 and Norsok R003/R002.

It allows for work in a safe and secure environment. Keep your crew safe from falling objects and bad weather.